SERVICE DETAIL

Welding service

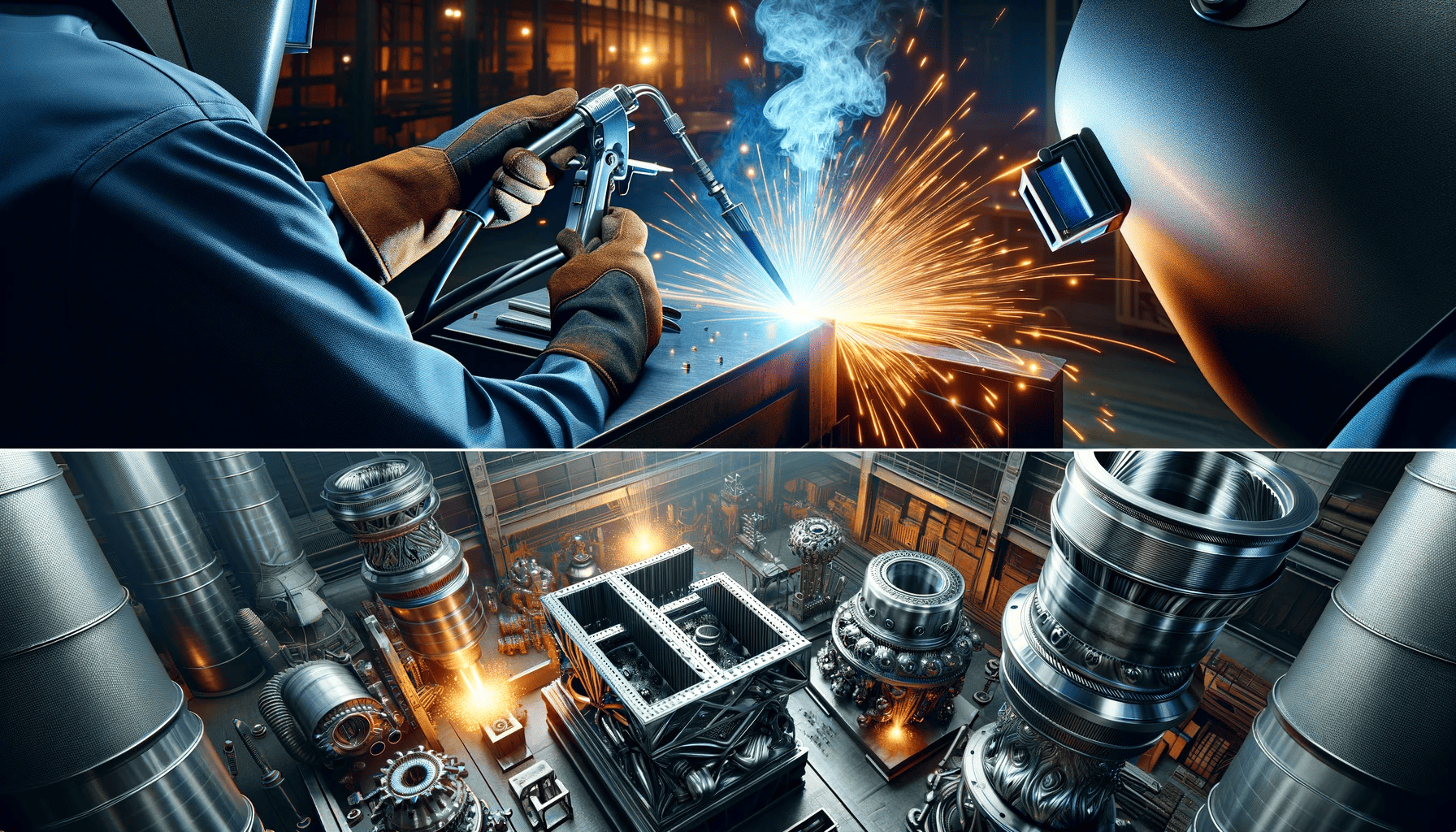

One Aluminium offers a bespoke welding service, expertly joining materials by controlled localised heating and melting. Catering to a range of metals including black steel, stainless steel, and aluminium, we tailor our welding methods to ensure permanent and safe bonds, suitable for long-term operation. Our welding types vary, designed to meet the specific needs and construction of each project.

Material Specific Methods

We select the appropriate welding joint and method based on the material to guarantee durability and structural integrity. This bespoke approach ensures each weld is optimal for its intended application

Rigorous Preparation

Metal preparation is crucial in our welding process. We ensure precision in edge beveling, thorough cleaning, and precise alignment for welding, establishing a robust foundation for a superior weld

- Customised welding for black steel, stainless steel, and aluminium

- Thorough metal preparation including beveling and cleaning

- Specific welding methods for different material properties

- Use of protective gas shields for oxidation-prone materials

- Use of protective gas shields for oxidation-prone materials

- Adherence to safety and quality standards throughout the process

Any Questions?

If you have any questions, get in touch and a member of our team would be happy to help out.

WHY CHOOSE US

Uncompromising Safety Standards

Safety is paramount in our welding operations. Our facility is equipped with advanced ventilation systems and protective gear to safeguard our team and maintain the integrity of the materials we weld. We discourage untrained welding attempts due to the significant risks involved

We can weld black steel, stainless steel, and aluminium with specialised techniques for each.

We meticulously bevel, clean, and tack the metals to ensure stability during the welding process

We follow strict safety protocols, including using a well-ventilated space and protective clothing and masks for our workers

Yes, we customise the welding method to suit the metal type and the project requirements

By adhering to stringent preparation and welding protocols, we guarantee high-quality, durable welds

Properly executed welding should not weaken the material. Our skilled technicians use advanced welding methods to ensure that the joint is as strong as, or stronger than, the base materials. We take care to select the appropriate welding technique that corresponds with the material properties to maintain or enhance its strength during and after the welding process.